paint scratch test procedure|paint scratch tester : Big box store Applied Technical Services conducts paint scratch testing to simulate the stresses . 18+ Garotas de Programa em Niterói | Acompanhantes em Niterói. Top acompanhantes em Niteróis online agora. Encontre massagistas com fotos, vídeos e whatsapp de garotas .

{plog:ftitle_list}

WEBCoroas. Grupos de coroas gostosas do telegram. Melhores links de grupos e canais com o melhor do porno brasileiro. Fetiches Sexuais. Links de grupos e canais de fetiches sexuais do telegram. Putaria liberada com os desejos mais loucos e sensuais da internet. Figurinhas +18.

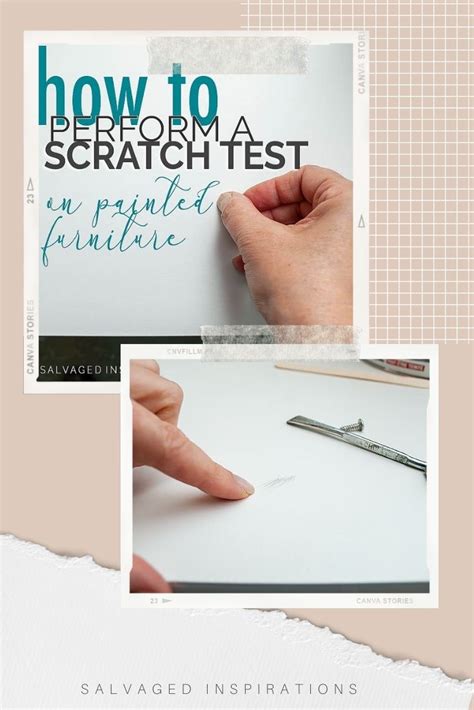

scratch testing for painted furniture

The procedure consists of applying the adhesive to a smooth substrate at a uniform thickness, then applying a rounded stylus at increasing amounts of pressure until the adhesive is removed. Quantitative results are measured in accordance with ASTM D2197 procedure specifications.Applied Technical Services conducts paint scratch testing to simulate the stresses .

There are three different procedures to assess the resistance of the coating to separate from the substrate and provide different adhesion analysis of the film: cross-hatch test, scrape .

compression tester adapter ih d236 d282

The scrape adhesion test measures the determination of the adhesion of organic coatings when applied to smooth, flat panel surfaces. It is helpful in giving relative ratings for a number of coated panels showing significant differences in adhesion. The tested materials are applied uniformly to flat panels, mainly some sort of sheet metal. When the materials have dried, the adhesion is determined by pressing panels under a rounded stylus loaded with increasing weight until the c.The scratch test is a simple engineering test method used to assess adhesive bonding between coatings and substrates. This Guide aims to help you get the best out of your scratch tester.There are several methods for testing the adhesion of a coating to a surface. They range from a simple cross cut test; through cross hatch testing, where a visual assessment is made; to .Applied Technical Services conducts paint scratch testing to simulate the stresses that materials endure daily. Manufacturers use coating tests to evaluate the adhesive properties of the coating, ensuring that the product or equipment .

ISO 4624:2016 specifies three methods (i.e. one dolly or two dollies on a painted panel and two dollies, one as painted substrate) for determining the adhesion by carrying out a pull-off test on .This document specifies three methods for determining the adhesion by carrying out a pull-off test on a single coating or a multi-coat system of paint, varnish or related product. These methods .

Discover the importance of paint scratch testing in ensuring durability and quality in coatings. Learn about industry standards, different testing methods, and the best equipment available.This document specifies a method for determining the resistance of a coating to scratches introduced by a usually hand-held loaded stylus. The test can be carried out using a point .

They will all fail the scratch test within a 24 hour period if enough pressure is applied. You cannot achieve its full bonding effect until it fully cures. Everyone always gives paint cure time to perform its best, but seem to neglect the same applies to primers in order to achieve its full potential. After final finish coat is applied and the .The standard procedure is as per ASTM D4541 and ISO 4624. . This test helps compare the scratch resistance of different coatings. It is ideal for providing relative ratings for a series of coated panels exhibiting significant differences in .Having prepared a surface, applied a coating and measured the wet and dry film thickness, a lot of time and money will have been wasted if the coating does not adhere to the substrate.. The greatest single cause of paint adhesion failure is poor surface preparation. The adhesion of a coating to a substrate is typically affected by the cleanliness of the surface and the profile, .Scratch hardness testing is often performed in conjunction with other hardness tests, such as Rockwell hardness testing or Brinell hardness testing. How to perform a scratch hardness test To carry out a scratch hardness test, a mechanised scratch hardness tester is recommended. This allows you to clamp a test panel which is slowly moved whilst .

ASTM D7187: Standard Test Method for Measuring Mechanistic Aspects of Scratch/Mar Behavior of Paint Coatings by Nanoscratching Abrasion Resistance Agents for Paints, Coatings and Inks View the full range of abrasion resistance agents available today, analyze technical data of each product, get technical assistance or request samples.Scratch testing is a test method used to characterise the adhesion of surface coatings. The test involves drawing a hard tool (indenter) across the surface coating with increasing load, whilst using a calibrated load cell to record the measurements applied. At a critical force, the coating will either delaminate from the substrate or the .

ISO 2409 Paint and Varnishes — Cross-cut test4 3. Summary of Test Methods 3.1 Test Method A—An X-cut is made through the film to the substrate, pressure-sensitive tape is applied over the cut and then removed, and adhesion is assessed qualitatively on the 0 to 5 scale. 3.2 Test Method B—A lattice pattern with either six or

A scratch test is a simple and widely used method to measure the hardness and adhesion of materials, such as coatings, films, or composites. It involves dragging a sharp tip across the surface of .

This test relies on the interpretation of each individual tester and it is therefore possible for the results to differ from user to user. A refinement of the knife method is the St. Andrews Cross Cut Test, so called as the cut angle simulates the white cross depicted on .The Hoffman Scratch Hardness Tester was developed for the comparative evaluation of scratch resistance and adhesion of many types of coatings. Small size for in the field or plant testing; Flexible design – can apply more than 2400 gram force; Easy to use and operateASTM D3359-23 Standard Test Methods for Rating Adhesion by Tape Test covers X cut and crosshatch tape and peel methods. . The ASTM D3359-23 standard details procedures for assessing the adhesion of coating films applied to metallic . at the simplest level, involves the examination of the paint film removed after an applied tape is peeled .• Scratch resistance ISO 1518; ASTM 2793 • Erichesen cupping test ISO 1520; DIN 50102; B.S. 3900; NFT 30019 • Pencil hardness ASTM D3363 • Taber abrasion resistance ASTM D821; DIN 53774; ANF T 30015 • Heat resistance - - - - - - - - - - • Humidity resistance test ISO 6270; DIN 50017; B.S. 3900 F2 • Kesternich sulphur test ISO 3231 .

Assess the severity of the paint scratches by conducting a visual inspection, running a fingernail test, checking for paint transfer, and considering the scratch’s location and size. Prepare your car for the scratch removal process by gathering necessary supplies, washing and drying your car thoroughly, assessing the scratch again, and .The scratch adhesion properties of paint coatings or ceramic coatings are routinely evaluated using the progressive scratch test performed on Bruker’s scratch test system. In figure 5, the Fz, COF and R (ECR) values have been plotted against the distance for the scratch test conducted on a diamond-like carbon layer (DLC) coating on a steel .The Paint Adhesion Test Kit, (P.A.T.), contains all of the tools and materials needed, except for the multi-tooth cutter blade, for conducting adhesion tests on paints applied to a flat, uniform surface in accordance with ASTM Test Method D3359, method B and DIN Standard No. 53151. There are two kits available: The Cross Hatch Test Kit (12596) is great for any type of flat .

1.1.1 Usual Procedure of the Scratch Test The scratch test consists of pressing a diamond stylus onto the surface of the coating, using either a constant or an increasing load, whilst moving the sample at a constant speed (Figure 1). The test at constant load may be a single-pass scratch test or a multiple-pass scratch test. scratch experiment even for rough or curved surfaces. Scratch velocity and scratch path followed by the in-denter on the specimen surface are defined by the opera-tor. Scratch velocity is typically held constant through-out the scratch experiment and can be set between 0.05 µm/s to 2.5 mm/s. For these tests, a velocity of 25 m/s was used.

a) Bend test, b) Scratch hardness test, c) Cupping test, and d) Pull off test. ~ 2. Bend Test 8 2.1 Outline ofthe Method - This is an empirical test for assessing the resistance of a coating of _ paint, varnish, etc, to cracking and/or detachment from a metal substrate when subjected to ~ bending round a cylindrical mandrel. (; 2.2 Apparatus The relationship between deformation and surface properties of both the scratch stylus and coated substrate is complex.3 Briscoe et al. proposed the concept of scratch mapping, a test procedure to map the scratch response to different conditions by varying contact load and contact strains.4,5 Nevertheless, this approach requires many experimental efforts.

ISO 4624:2016 specifies three methods (i.e. one dolly or two dollies on a painted panel and two dollies, one as painted substrate) for determining the adhesion by carrying out a pull-off test on a single coating or a multi-coat system of paint, varnish or related product. These test methods have been found useful in comparing the adhesion .method to test the scratch hardness of coatings. In this test, pencils in a range of 8B to 10H hardness-grade are used. The pencil is moved scratching over the surface under a 45° angle with a constant pressure. Then an optical assessment is carried out to see which pencil hardness damages the surface. Delivered with a set

The test simply involves placing a fingernail on the surface and attempting a quick scratch. A properly cured and abrasive resistant coating should not scratch. The way a fingernail test is performed can be categorized as indenting, shearing and grazing actions, which vary by the way the nail interacts with the surface.

ASMT D3363 is a test method designed to evaluate the hardness of a coating through the use of pencil or drawing leads. . Micom offers ASTM D3363 testing as part of its paint testing . This method consists of evaluating the surface aesthetics of the coating following an attempt to scratch it with a pencil of known hardness at a 45o angle by .The set of Elcometer 3080 Hardness Testing Pencils is a simple but effective technique to evaluate the hardness of many coatings. The pencil lead, prepared beforehand by using the special pencil sharpener and rubbing it on fine abrasive paper (400 grade), is maintained at an angle of 45° and pushed with uniform pressure on to the sample, leaving either a superficial .The test can be carried out on finished objects and/or on specially prepared test specimens. Although the method is applicable to paint on hard (e.g. metal) and soft (e.g. wood and plaster) substrates, these different substrates need a different test procedure (see Clause 8).The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. . (Kratztest) (en: Technical mechanical tests ? Adhesion tests (scratch test)) [32] Fiat Material Standard 50488/01, Chip resistance test for paints, enamels, protective coatings and related products [33 .

compression tester adapter inclued for 14mm

Types of allergy skin testing. The types of allergy skin testing include: Prick/puncture/scratch skin test involves applying a diluted allergen with a small prick, puncture, or scratch to the skin’s surface.. Intradermal test involves injecting a diluted allergen below the skin surface using a tiny needle. Doctors sometimes use intradermal tests after a negative .

WEBUpdate: the site seems to be dealing with some heat from Depop due to one of the forum threads. Some other redditors have taken it upon themselves to get the site taken down bc of finding their content in the forum. This seems .

paint scratch test procedure|paint scratch tester